Depending upon your temperament as an electrician, finding faults can be either the bane of your life or smugly satisfying when you discover their cause. YouTube is full of angry sparkies pointing out where they have discovered some ‘Donald DIY’ enthusiast (or even sometimes Fully Qualified Fred) has wired up something lethal, or maybe extolling their marvellous detective skills at finding the source of some devious electrical nuisance. The past few weeks I have had my share of both, though I think that venting my spleen on social media is less than helpful to the wider world. Below I share some insights about common problems I’ve observed:

LED dimmers and light switches

With the shift towards more energy-efficient lighting, lots of installers have fitted LED lights and (for those who want mood lighting) LED dimmer switches to control them. In my customer’s property, a dimmer switch controlled four retro Edison bulbs above a long table, similar to those shown below. One day, she observed the bulbs glowing normally one minute, then all four just fading out simultaneously. So, this first clue of fading together indicates the bulbs were probably OK, but there was some fault on the supply side.

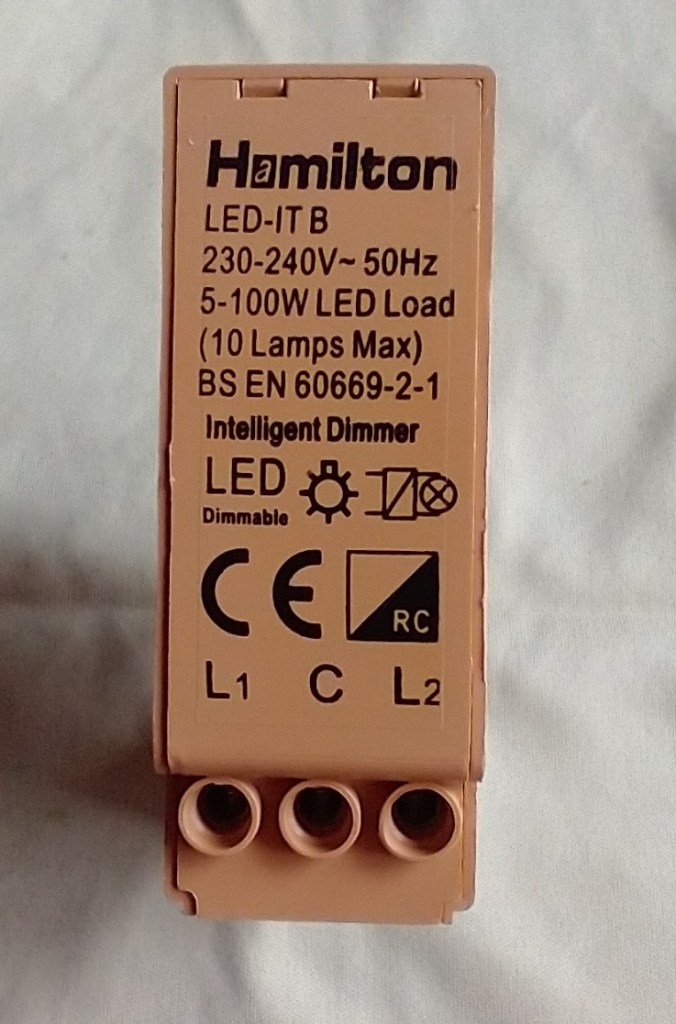

The first thing I noticed was that these bulbs were all 60W. So four of them makes a beefy 240W (about 1 Amp) of power being consumed on a single lighting circuit. I then found that the back of the dimmer switch says it is limited to a maximum of 100W. An open-and-shut case of overloading the dimmer. Be aware: not all dimmers work with LEDs and LED dimmers don’t work well with filament bulbs, either!

These (rather elegant) Hamilton dimmer switches are not cheap, and because they are hand finished, replacement units take around 8 weeks (!) to deliver from ordering. However, a quick trip to our local Malmesbury supplier (huge thank you to C&J Electrical) found a spare 400W non-LED dimmer switch on the shelf. No sooner had I fixed that, when the customer showed me another faulty Hamilton toggle switch controlling some stairwell lights:

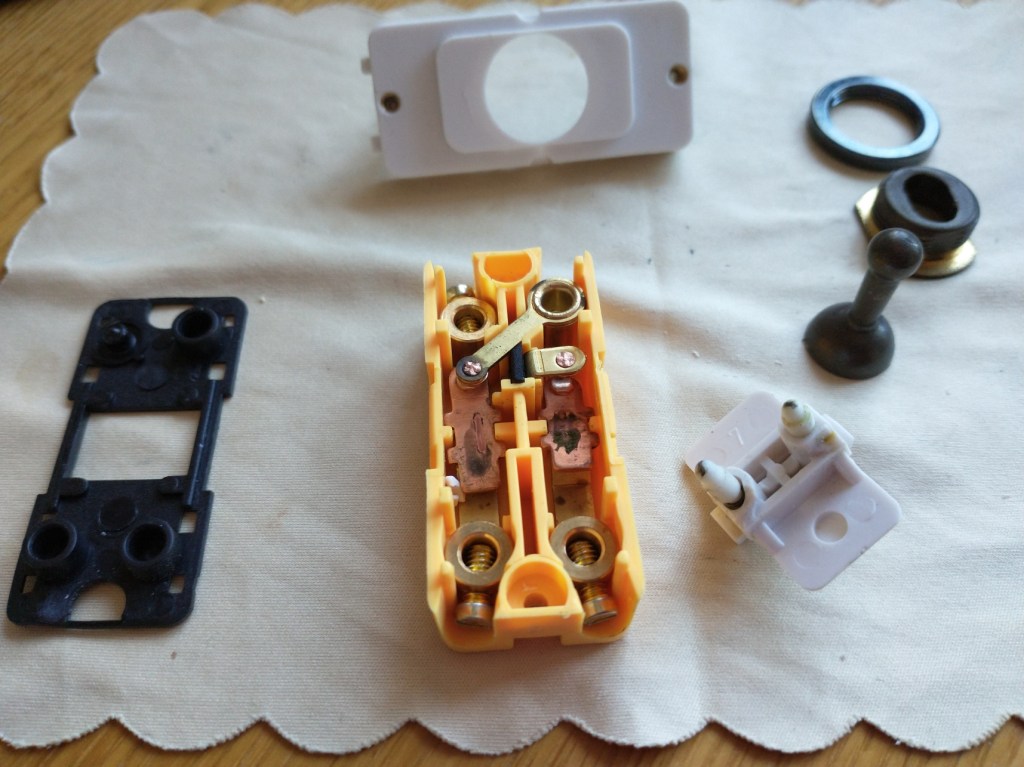

Unlike the dimmer switch (which is full of printed circuit boards and silicon chips), a toggle switch is essentially a mechanical device at its heart. Sure enough, stripping down the faulty switch (above) revealed the plastic rocker had broken on one side, making the switch useless. Fortunately (again because of lead-times involved) I was able to get this one repaired and operational. [I really must mention here that Hamilton is a good brand – the dimmer was simply down to incorrect bulb/dimmer selection and the toggle was probably bashed on the side at some point pre-installation judging by the visible damage.]

Dead shorts

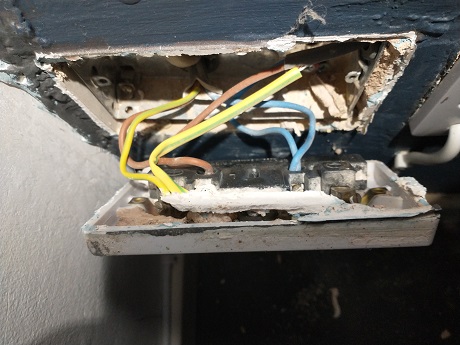

When you visit a Housing Association property (as opposed to visiting a private house) you might expect a certain basic standard of electrical installation. The construction industry has had very light touch regulation for years (witness disasters like Grenfell Tower and Lakanal House) and the lack of enforcement of safety has made most companies rather complacent. The following is a photo of a socket I found in a Housing Association property recently, and is typical of the standard of workmanship in our housing stock:

To be fair to the electrician involved, this occurred after the socket was installed, but it illustrates how things can go wrong. I was only initially called in to move another socket for this customer, but found a dead short on the ring circuit, which led to this discovery. Interestingly, the plaster bridging across the contacts here wasn’t the actual fault (though its not good either): the cable going to the switch on the right of the photo had a dead short somewhere inside. After replacing this short length of cable, the insulation resistance was back where it should be, though I left the actual bit of faulty cable with the customer so they could wave it under the nose of the landlord. What annoyed me here was the property had allegedly been “inspected” by a registered electrical contractor only a few months previously (according to the label they left behind on the consumer unit). Inspected should mean actually tested, not just a visual once-over and slap on a conformity label.

Red hot lights

G9 lights were once all the rage in UK kitchens, since their size allows them to be fitted into small locations, typically under cabinets or kitchen hob extractors to reduce shadows and improve visibility. This triangular one was fitted in a friend’s kitchen and had stopped working. Despite ‘only’ being 12V, these lights get very hot (being rated at 30W), and their lifespan is not exactly huge. The photo doesn’t reveal the white cable sheathing being partially melted due to the heat build up above the light, and goodness knows what the kitchen fitter was thinking using PTFE tape over twisted wires as an electrical joint. Mercifully, the bulbs can usually be replaced with a low power (3-4W) LED equivalents or even better, disposed of in the bin and replaced with proper units. Just get them wired in properly though! #youneedasparky